Mission Style Umbrella Stand

|

This information has been reprinted from a 1912 Popular Mechanics publication titled "Mission Furniture And How To Make It".

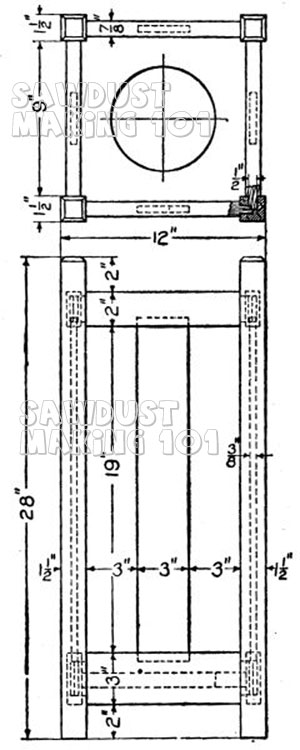

The umbrella stand shown in the accompanying illustration will be found quite appropriate for the hall or reception room that is furnished in mission style. It can be made of any of the furniture woods, but quarter-sawed oak gives the best results. The stock necessary to make this stand can be secured from the mill ready cut to length, squared and sanded, and is given in the following list:

First square up the posts and bevel the tops as shown in the detail sketch. Place them side by side, on a flat surface with the ends square and lay out the mortises with a try-square on all four pieces at the same time. This will insure your getting them all straight and of the same height. Now lay out the tenons on the rails in the same manner and cut them to fit the mortises in the posts. Mortises should also be cut in the rails for the ends of the side slats as shown. Try all the joints and see that they fit tight and square. Glue two sides of the stand together and let them dry for at least 24 hours, then glue the remaining parts, being careful to get everything together perfectly square.[34] The bottom board can now be fitted in place. It should have a hole cut in it for the drip pan. The pan should be about 6 or 7 in. in diameter. One suitable for the purpose can be purchased in any hardware store. The bottom board can be fastened to the rails with nails driven from the under side, or cleats can be nailed to the rails for it to rest upon. When the stand is complete, scrape all glue from about the joints and go over the whole with fine sandpaper, removing all rough spots. Apply the finish you like best, or the one that will match your other furniture. Should the builder want an entire hand-made stand, the drip pan may be beaten into shape from sheet brass or copper. This kind of work is known as repoussť. After beating the pan into shape, it can be finished in antique, old copper or given a polished surface, as desired.

|