This information has been

reprinted from a 1912 Popular Mechanics publication

titled "Mission Furniture And How To Make It".

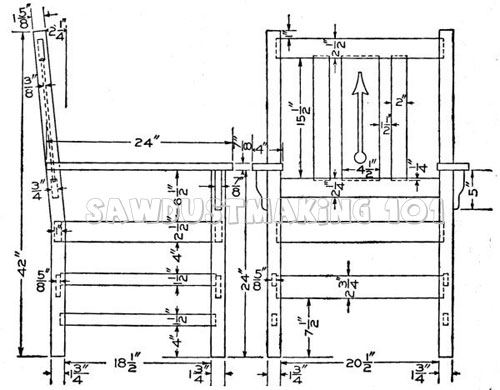

Extendable Table

This extension table should

be made of some hard wood, preferably white oak. It will

be a difficult matter to secure legs of the sizes

indicated in solid pieces of clear stock. It will be

possible, however, to secure them veneered upon

white-pine cores. If the veneering is properly done

these will serve the purpose very well, the lighter

weight, due to the white-pine core, being an advantage.

The circular facing is best made by first sawing a

segment of the circle of the size wanted and then

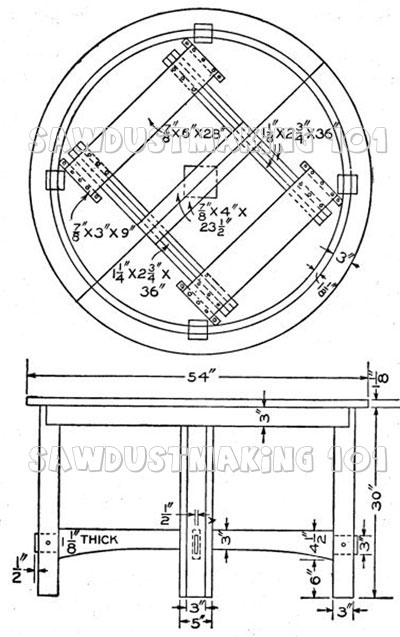

veneering the outer surface of this. Order the following

stock:

- 4 legs, 3 by 3 by 30-1/2

in., S-4-S.

- 1 leg, 5 by 5 by 30-1/2

in., S-4-S.

- 4 rails, 1-1/8 by 5 by 23

in., S-2-S.

- 4 facing segments, 1-1/8

by 3-1/4 in. on a 24-in. radius.

- 1 top, 1-1/8 in. thick on

a 27-in. radius, S-2-S;

- 3 extra boards, 1-1/8 by

12 by 55 in., S-2-S.

- 4 slides, 1-1/8 by 2-3/4

by 36-1/2 in., S-4-S, maple.

- 2 slides, 1-1/4 by 2-3/4

by 36-1/2 in., S-4-S, maple.

- 4 frame pieces, 7/8 by 3

by 9 in., S-4-S, maple.

- 2 frame pieces, 7/8 by 6

by 28 in., S-4-S, maple.

- 2 frame pieces, 7/8 by 4

by 23-1/2 in., S-4-S, maple.

There are various ways of

arranging the slides to work one with the other. Several

patented devices are on the market that permit a ready

adjustment with but little effort and are used

extensively by commercial manufacturers. The amateur

will do well to secure a set before he undertakes to

work these slides to shape.

| Equalizer

Slides |

| Super

easy one handed extension. As you pull on one

half, the other side moves away.

Equalizer

Slides

|

|

Prepare the legs by cutting

them to length. Lay out and work the mortises. The ends

of the facings are to be tenoned and housed into the

posts. Prepare the rails by cutting the tenons and

shaping the lower edges as shown in the drawing. Prepare

the top. After this, assemble this much of the frame,

using plenty of clamps and good hot glue.

Next get the under frame and

the slides ready and attach them as shown. There will be

needed plenty of glue blocks for reinforcing the facing

where it is fastened to the top, etc.

For a finish, apply a filler

colored, as desired. Upon this, after it has hardened

and been sanded with No. 00 paper, apply a coat of

shellac. Upon the shellac apply successively several

coats of some good rubbing varnish. Rub the first coats

with haircloth and the final coat with pulverized pumice

and crude or linseed oil.

If an effect is wanted that

will contrast, stain the wood first with a water stain.

Sand this lightly when dry, then apply a second coat of

stain diluted one-half with water. Again sand and then

apply a thin coat of shellac. Sand this lightly, and

apply the filler and the varnish as described above.

|

Table

Pins

Align

tops with Table Pins..

Table

Pins

|

|

Align-N-Lock

Performs

both functions simultaneously...

Align-N-Lock

|

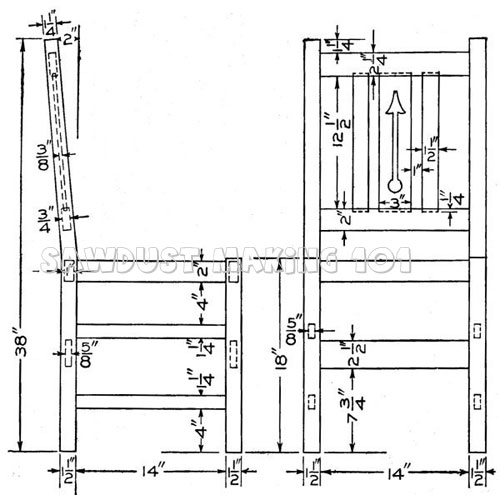

Arm Dining Chair

This armchair will look well

if made of plain-sawed oak. Quarter-sawed oak might be

used, or black walnut if desired. The stock bill

specifies the various parts mill-planed to size as far

as possible. If some amateur craftsman should prefer to

[80]do his own surfacing,

thereby saving somewhat on the expense, he should add

1/4 in. to the width of each piece, providing the stock

is mill-planed to thickness. It is hardly profitable to

get stock entirely in the rough if the work is to be

done by hand. The following is the stock bill:

- 2 front posts, 1-3/4 by

1-3/4 by 25 in., S-4-S.

- 1 piece for back posts,

1-3/4 by 6 by 43 in., S-2-S.

- 2 arm pieces, 7/8 by 4 by

24-1/2 in., S-4-S.

- 2 seat rails, 1 by 2-1/2

by 22 in., S-4-S.

- 2 seat rails, 1 by 2-1/2

by 24 in., S-4-S.

- 4 lower side rails, 5/8 by

1-1/2 by 22 in., S-4-S.

- 2 front and back lower

rails, 5/8 by 2-3/4 by 24 in., S-4-S.

- 1 back rail, 3/4 by 2-1/4

by 24 in., S-4-S.

- 1 back rail, 3/4 by 2-1/2

by 24 in., S-4-S.

- 2 slats, 3/8 by 2 by

16-1/2 in., S-4-S.

- 1 slat, 3/8 by 4-1/2 by

16-1/2 in., S-4-S.

- 2 braces, 7/8 by 2-1/2 by

5-1/2 in., S-2-S.

The design shown is for a

chair in which the width of front and back is the same.

Also the back leg parallels the front below the seat. In

commercial practice the backs are usually made somewhat

narrower than the fronts and the back leg is slanted

somewhat below the seat as well as above. As this

construction necessitates sloping shoulders on all

tenons it complicates the problem when the work is not

done by machinery. The ambitious amateur may readily get

the proportion of slant by measuring common chairs. For

mission effects the chair looks well with front and back

the same width.

Prepare the front posts first

and then the rear. The rear posts are to be cut from the

single piece of stock specified. By proper planning both

pieces may be gotten out without trouble. Lay off and

cut the mortises.

Saw the rails to length and

lay out and cut the tenons. The back rails are to have

mortises in their edges to receive the ends of the

slats. Instead of [81]

tenoning these slats make mortises large enough to

receive the whole end—in other words, house the ends.

Shape the two arms, then glue

up the back and then the front of the chair. After the

glue has set sufficiently, assemble the remainder of the

parts.

Thoroughly scrape and

sandpaper the parts and then apply the finish.

For a seat, either a leather

cushion may be placed upon slats or the bottom may be

upholstered in the usual manner, using webbing on heavy

canvas, and then felt or hair with a top of canvas and

leather; the whole being firmly fastened with tacks and

the leather with ornamental nails.

Side Chair

A companion piece to the

chair with arms and the sideboard is the side chair

illustrated herewith. It should be made of the same kind

of wood and finished to correspond with the armchair.

Order the following stock list:

- 2 front posts, 1-1/2 by

1-1/2 by 18-1/2 in., S-4-S.

- 1 piece for back posts,

1-1/2 by 5-1/2 by 38-1/2 in., S-2-S.

- 4 seat rails, 1 by 2 by 17

in., S-4-S.

- 4 lower side rails, 5/8 by

1-1/4 by 17 in., S-4-S.

- 2 lower front and back

rails, 5/8 by 2-1/2 by 17 in., S-4-S.

- 1 back rail, 3/4 by 2-1/4

by 17 in., S-4-S.

- 1 back rail, 3/4 by 2 by

17 in., S-4-S.

- 1 slat, 3/8 by 3 by 13-1/2

in., S-4-S.

- 2 slats, 3/8 by 1-1/2 by

13-1/2 in., S-4-S.

Square up the front posts to

length. From the single piece specified cut out the back

posts, giving them the amount of slant indicated in the

drawing. Set these four posts upright in the positions

they are to occupy relative to one another in the

finished piece, and mark off, as with penciled circles,

the approximate locations of mortises. After this, lay

them on the bench side by side, even the lower ends and

locate accurately the ends of the mortises. Gauge their

sides.

Saw the rails to length and

lay out the shoulder lines and the cheeks of the tenons

and cut them. Plan to house the ends of the slats in the

back rails.

While the drawing shows a

chair in which the front and back are of equal width,

the amateur may make the back narrower if he so desires.

A measurement of a common chair will give the

proportions.

Place the front and the back

in the clamps and after the glue has had time to harden,

assemble the remaining parts. Thoroughly scrape and

sandpaper all the parts, carefully removing any surplus

glue. Wood finish will not "take hold" where any glue

has been allowed to remain.

The seat may be given the

same treatment as suggested for the armchair. This

should not be done, however, until the finish has been

applied.

A simple finish is obtained

by the application of a coat of paste filler of a soft

brown color, if oak has been used. Apply and clean this

off in the manner directed by the manufacturers and

after it has had 24 hours in which to harden, sand it

lightly with No. 00 paper. Over this apply a thin coat

of shellac. Allow this to harden, then sandpaper lightly

with fine paper. Upon the shellac apply several coats of

some good rubbing wax. Follow the directions that are to

be found upon the cans, being careful not to apply too

much at a time. If too much wax is applied, it stays in

the small pores of the wood and produces an ugly

chalk-like appearance.

|