|

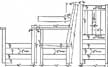

Mission Style Curved Back Arm Chair

The arm chair, the picture and drawing of which is given herewith is a companion piece to the rocker described on another page. With the exception of the back-legs the stock bill which follows gives the thicknesses and widths exact. To the length, however, enough has been added to allow squaring up the ends.

Begin work by squaring up the ends of the front posts and shaping the rear ones Chamfer the ends of the tops and bottoms slightly so that they shall not splinter through usage. Next lay out the mortises and tenons. The curved horizontals for the back should now be prepared and steamed as described on another page. The curved form to which the steamed piece is to be clamped to give shape to it should be curved slightly more than is wanted in the piece, as the piece when released will tend to straighten a little. The arms of the chair may be shaped while these pieces are drying on the forms. The rails of the front and back may be tenoned, too. It should be noted that the front of the chair is wider than the back. This will necessitate care in mortising and tenoning the side rails so as to get good fits for the shoulders The bevel square will be needed in laying out the shoulders of the tenons. Assemble the back, then the front. When the glue has hardened on these parts so that the clamps may be removed, put in the side rails or horizontals and again adjust the clamps. The arms are to be fastened to the posts with dowels and glue. The seat, it will be seen from the drawing, is to be a loose leather cushion to rest upon slats. These seat slats may be fastened to cleats which have been previously fastened to the inside of the front and back seat rails or they may be "let in" to these rails by grooving their inner surfaces before the rails have been put in place. The latter method is more workmanlike, but more difficult. A cushion such as is shown can be purchased ready made up, or it may be made by the amateur by lacing together two pieces of Spanish leather cut to size and punched along the edges so as to allow a lacing of leather thong. It may be filled with hair or elastic felt such as upholsterers use. Probably the simplest finish that can be used is weathered oak. Put on a coat of weather oak oil stain, sandpaper lightly when dry and then put on a very thin coat of shellac. Sand this lightly and follow with two or more coats of floor wax put on in very thin coatings and polished well. |